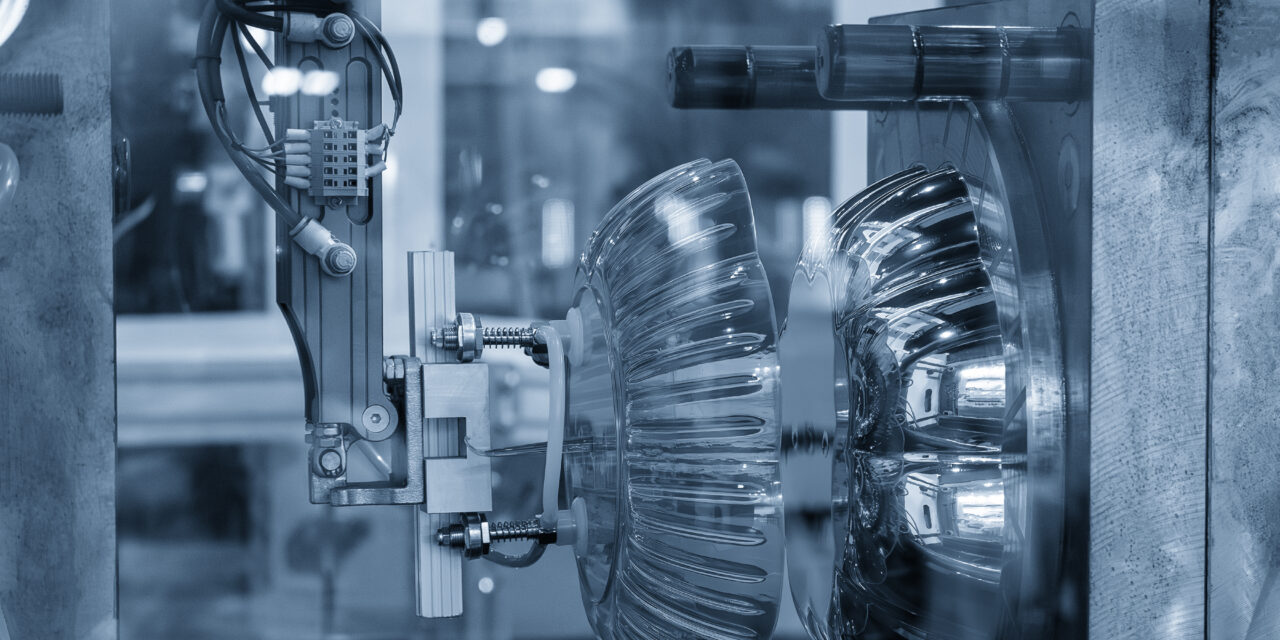

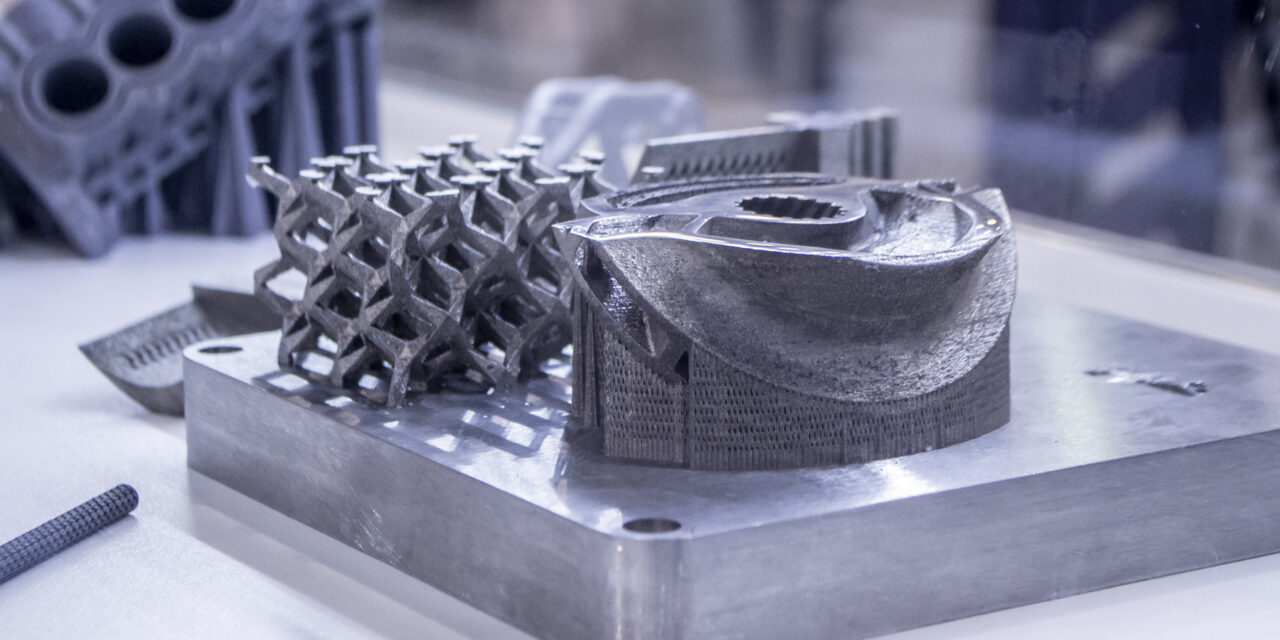

Additive Manufacturing (AM) is revolutionizing how we design and produce components, offering unmatched geometric freedom, material efficiency, and on-demand fabrication. Its applications span from aerospace to biomedical engineering. However, widespread industrial adoption still faces obstacles such as: Ensuring process repeatability and mechanical consistency Achieving real-time quality assurance Optimizing build parameters and support strategies These issues present a clear opportunity for innovation in monitoring, control, and predictive process management.

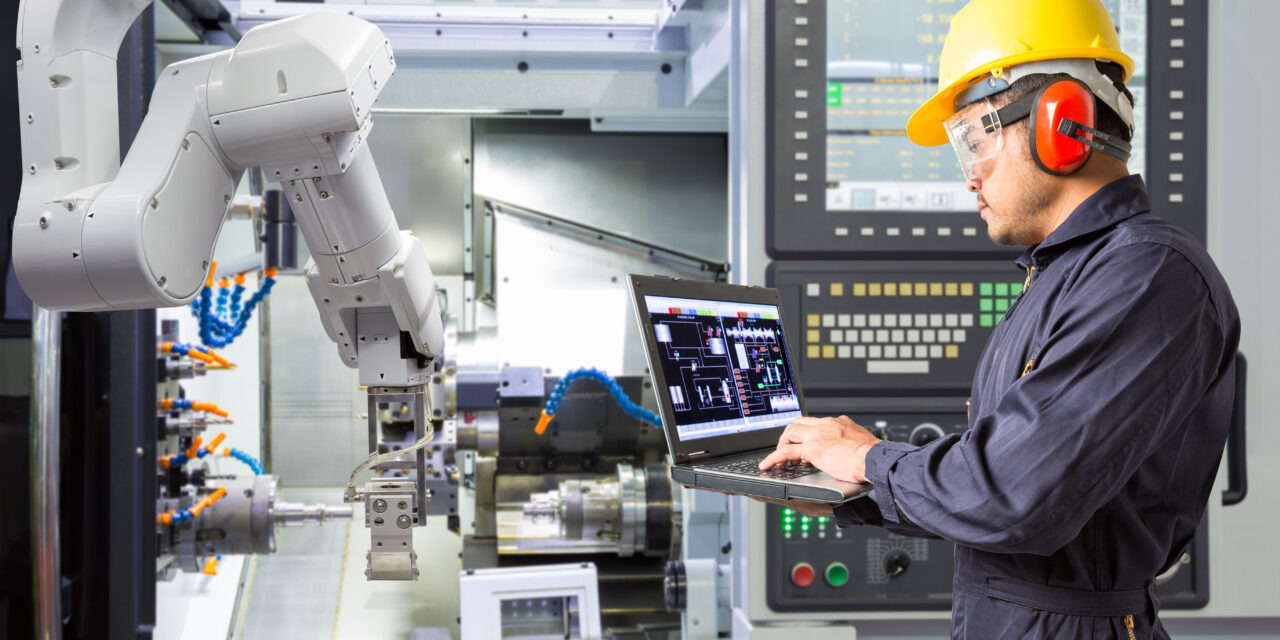

At SMARC, we are actively crafting an AI-IoT framework tailored for next-generation additive systems. Our goal is to enable intelligent sensing, predictive analytics, and adaptive control through scalable, cost-effective technologies. Rather than relying on traditional infrastructure-heavy solutions, we aim to build tools that bring insight and stability to AM environments, bridging lab-scale innovation with real-world constraints. This initiative is currently in its conceptual design phase, driven by SMARC’s commitment to building practical, research-aligned solutions. If you are interested in learning more about our AI-driven additive system or discussing potential applications, please don’t hesitate to reach out.

Opportunities & Challenges in Additive Manufacturing:

SMARC’s Framework for Scalable Intelligence: