Tool Wear, Tolerance, and the Cost of Precision:

Precision machining lies at the heart of advanced manufacturing, demanding accuracy, surface finish, and repeatability under high-speed and high-load conditions. While CNC and high-performance machine tools have evolved, several key challenges remain at the forefront of industry concern:

Accurate tool wear prediction without interrupting production

High cost and complexity of sensor integration for monitoring

Process optimization across varying materials and cutting parameters

These constraints limit scalability, particularly for SMEs and retrofitted equipment.

AI-Driven Insights from Minimal Signals:

At SMARC, we have developed a machine learning–powered tool condition monitoring system that extracts actionable insights using low-cost, non-invasive signals. Our recent work, presented at the CIRP ISEM 2025 conference, demonstrated that electromotive force (EMF) and AC motor slip can serve as reliable indicators for tool wear, achieving classification accuracies exceeding 90%.

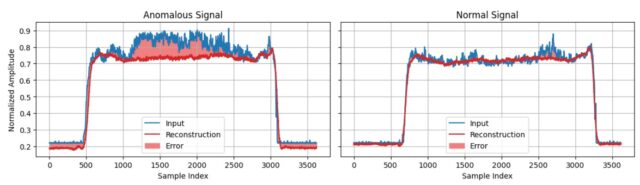

To visually illustrate this, the figure below presents side-by-side comparisons of a normal and anomalous signal, clearly showing how the system differentiates between stable and worn tool conditions through reconstruction error. This successful prototype showcases our ability to deliver cost-effective yet high-precision solutions in machining.

This project reflects our broader mission: democratizing advanced machining intelligence, delivering accuracy and robustness without the dependency on costly instrumentation.

If you are exploring digital solutions in machining, predictive maintenance, or tool life optimization, please don’t hesitate to reach out.